Friday, May 17, 2024

Friday, May 17, 2024  Friday, May 17, 2024

Friday, May 17, 2024

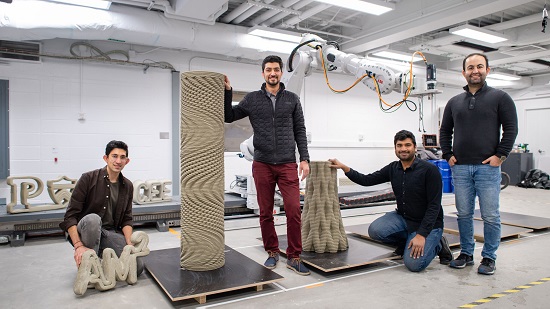

Engineers at Princeton University are deploying lasers to precisely evaluate a major drawback of 3D-printed cement — the material’s resistance to fracture. The researchers hope that progress in this area could lead to a wider use of additive manufacturing in cement-based structures. The long-term goal is to develop better materials using additive techniques that lead to innovative designs and functions.

Cement is the major ingredient in the concrete that makes up much of modern construction — including buildings, roads, runways, bridges and dams. In recent years, as 3D printing has demonstrated advantages in efficiency and versatility, there has been a growing interest in applying the technology to construction.

But compared to conventionally cast concrete, the 3D-printed alternatives can be subject to cracking, particularly in areas between different layers of concrete. Researchers attribute this to non-uniform microstructures introduced by the layering process used in 3D printing. Princeton researchers have used a new test to better understand this cracking at a microscopic level. Their findings suggest that by properly characterizing the fracturing properties, 3D-printed concrete could be just as strong or even stronger than cast concrete.

In a study in the journal Cement and Concrete Composites, Princeton researchers demonstrate a new testing method that uses lasers to cut precisely located grooves in 3D-printed cements. By controlling the power and speed of the laser, the researchers can control critical features such as the grooves’ depth and shape. This control allows for far more accurate testing than conventional methods.

Keep reading on engineering.princeton.edu